75 years collective product development

Certified WHMA

Servicing Australia-wide

Keeping your wheels moving, all ways

Whether you’ve got a fleet of passenger vehicles, commercial truck or large speciality vehicle, Harness Master NSW offers maintenance and custom-made automotive wiring harness services. Covering all industries from rail, defence and heavy industry to local and small businesses, our experienced team can repair, replace, design and manufacture an electrical solution to suit your needs and required industry standards.

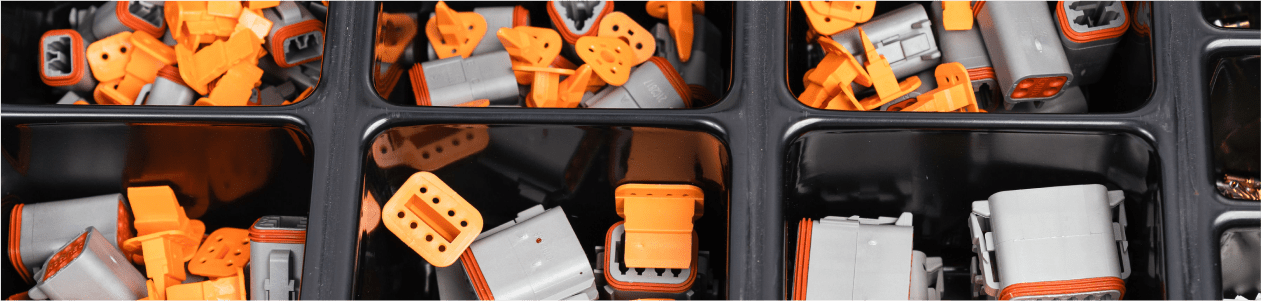

Choosing an aftermarket automotive wiring harness can help improve the durability and reliability of your vehicle’s electrical systems, while also allowing you to take advantage of aftermarket features and easily integrate future upgrades. At Harness Master NSW, we use only the highest-quality materials and components and always conduct rigorous quality assurance testing. If you need experienced assistance with your automotive wiring harness needs, contact our professional team today.

Streamlined supply chain for Glencore mine

Through the redeveloping of their parts and maintenance program, our team was able to help Bulga Mine’s maintenance planners and supervisor to create a bespoke, turn-key solution for increased reliability, availability and conformity across their fleet.

Multi-facted service solutions

At Harness Master NSW, we offer service solutions to suit both industry requirements and customer needs. With workshop, on-site or even self-install options, we ensure your equipment is kept up and running as efficiently and conveniently as possible. No matter how large or small, our expert team can tackle any challenge, including refurbishments, cab overhauls and custom applications and products.

Custom Solutions

At Harness Master NSW, we design and manufacture customised automotive electrical wiring harnesses for all industries. Our quality and innovative products are crafted to suit your specifications, modifications and unique needs. Our experienced team can help you build a unique solution that is not only long-lasting but also easy to install, maintain and service.

Whether you’re looking for something that doesn’t currently exist on the market or has been discontinued, we’re here to support you through every step of the process, from initial design to final testing and installation. No matter the challenge, the experts at Harness Master NSW can help you create a bespoke solution that will withstand even the harshest of conditions.

Product Refurbishments

If your existing automotive wiring harness could use a little refresh, the team at Harness Master NSW can help you with repairs and refurbishments. Our unique and programmatic approach ensures we replace and rebuild every product to the highest standard. Our comprehensive pre-work assessments and quality assurance testing guarantee your revived wiring harness will outlast and outperform your previous product.

Ensuring improved reliability and durability, our refurbishment services can also help improve your existing setup, giving you increased capabilities. At Harness Master NSW, our expert team uses only trusted and tested materials to rebuild the perfect automotive wiring harness for you.

Why Work With Us?

Low cost, high quality products

Increased reliability

Minimised downtime

Innovative solutions

Breakdown support

Simple installation and maintenance

MDG-15 compliant

Short lead time

Have peace of mind knowing you’ll always receive top-quality results within your budget when you work with Harness Master NSW. With upfront and transparent pricing, customisable and innovative design and manufacturing capabilities, plus on-going after-sales support, our experienced team are here to keep you moving, all ways,

Our Design and Manufacture Process

We ensure all our clients receive high quality and reliable products with our quality assured design and manufacture process.

-

Assess the application and purpose of the product to identify its function and its place in the greater machine schematic.

-

Assess the operating environment where the harness will be fitted or operate, taking into account factors such as load, heat, exposure to fluids, movement, vibration, and element exposure.

-

Apply our strict design and product standards to deliver a customised solution which optimises performance, installation, maintenance and serviceability for the harness application and operating environment.

Bring us your challenge!

Touch

Know what you want but not sure how to do it? Trust one of Australia’s leading wire harness manufacturers to bring your idea to life with quality, innovative and custom designs and builds.

admin@harnessmasternsw.com.au

admin@harnessmasternsw.com.au