75 years collective product development

Certified WHMA

Servicing Australia-wide

Discover products that outperform the alternatives

At Harness Master NSW, we offer easy to use, install, maintain and service electrical solutions that are long-lasting and high-quality. Using the latest technology, our experienced cable manufacturers can build innovative and customised products to suit your unique needs.

We design and deliver electrical harnesses for all industries, with our experienced and knowledgeable team ensuring your solutions meet required specifications and regulations. Experience the Harness Master NSW difference. Contact us today.

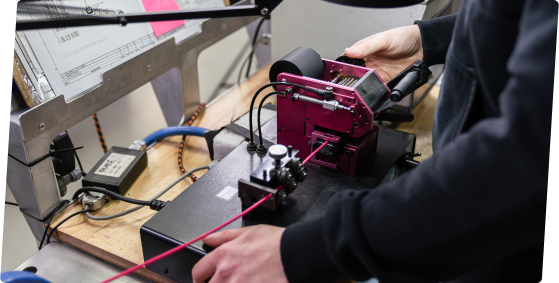

Our manufacturing capabilities include:

- Low & high-volume production runs

- Fast one-off prototyping

- Wire braiding

- Wire harnesses and cable assemblies

- Electronic circuit boards & assemblies

- Custom parts

- Connector over moulding

- Electrical enclosures, cabinets & brackets

- Inhouse 3D printing

Improved Production Solutions for HMS Group

The Harness Master NSW team provided HMS Group with a production-ready vehicle prototype that was simple, reliable and cost-effective to manufacture, ready to tackle harsh firefighting, military and mining environments.

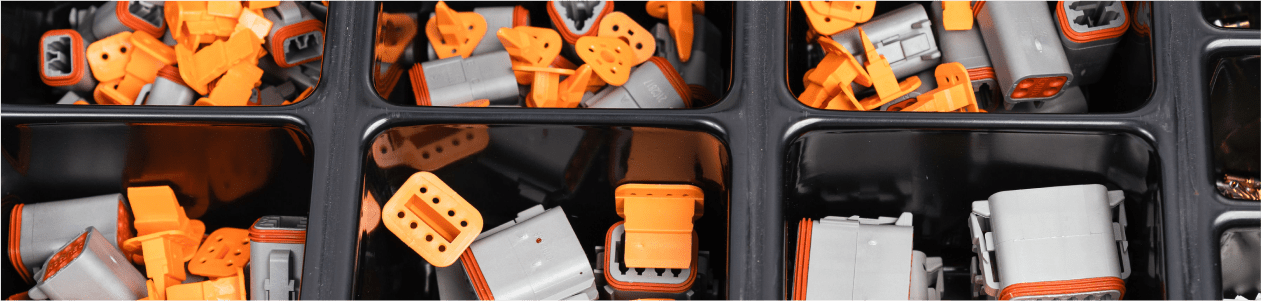

We design and manufacture wiring harnesses and cable assemblies that are:

- New / custom-made

- Aftermarket / OEM

- Remanufactured

Our harnesses can be designed with multiple specifications, modifications, materials and options to suit our customer’s specific needs. We are proud to invest our skills, experience and knowledge into creating new and innovative harness designs to address a range of common issues and problems experienced by our clients.

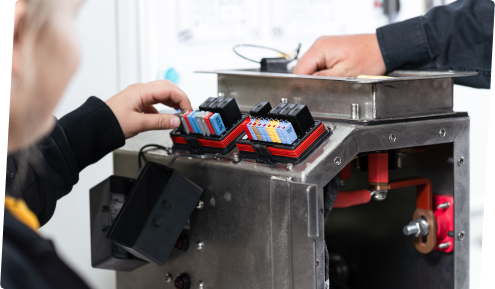

Electrical enclosures, cabinets and harnesses

We design, assemble and test printed circuit boards for a range of functions to ensure our clients (and their equipment) are kept safe.Our printed circuit boards can be manufactured into fully sealed modules by using encapsulation resin or mounted into a custom enclosure.

At Harness Master NSW, our team can provide all componentry required to utilise our in-house assembly capabilities, allowing us to fit out your product in a way that suits you.

Custom parts

Our team of electrical harness manufacturers and engineers are known for their ability to design and manufacture custom parts and products that either are currently not available in the market or have been discontinued. All our customised solutions are not only easy to install, maintain, service and reorder, each is also built with high-quality materials to ensure longevity and reliability.

The benefits that our manufacturing division deliver include:

Low cost, high quality products

Increased reliability

Minimised downtime

Innovative solutions

Breakdown support

Simple installation and maintenance

MDG-15 compliant

Short lead time

Have peace of mind knowing you’ll always receive top-quality results within your budget when you work with Harness Master NSW. With upfront and transparent pricing, customisable and innovative design and manufacturing capabilities, plus on-going after-sales support, our experienced team are here to keep you moving, all ways,

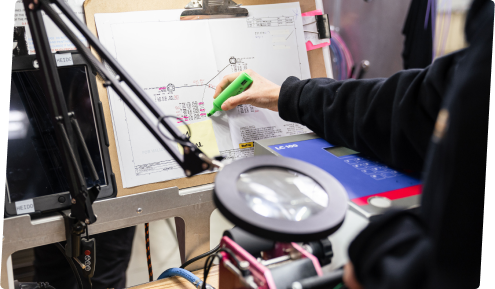

Designing and manufacturing the right product

We ensure all our clients receive high quality and reliable products with our quality assured design and manufacture process.

-

Assess the application and purpose of the product to identify its function and its place in the greater machine assembly.

-

Assess the operating environment where the harness will be fitted or operate, taking into account factors such as load, heat, exposure to fluids, movement, vibration, and element exposure.

-

Apply our strict design and product standards to deliver a customised solution which optimises performance, installation, maintenance and serviceability for the harness application and operating environment.

Bring us your challenge!

Touch

Know what you want but not sure how to do it? Trust one of Australia’s leading wire harness manufacturers to bring your idea to life with quality, innovative and custom designs and builds.

admin@harnessmasternsw.com.au

admin@harnessmasternsw.com.au